A new generation of the MATRIX precision seeder

The MATRIX mechanical precision seeder has been on the market for 10 years. For the 2025 campaign, GRIMME is presenting the latest generation of the 12- and 18-row MATRIX.

Published on August 16, 2024 - from Christina Klöcker

The MATRIX mechanical precision seeder has been on the market for 10 years. For the 2025 campaign, GRIMME is presenting the latest generation of the 12- and 18-row MATRIX. The focus of the new development included a compact design, optimised weight distribution and increased driver relief in terms of adjustment options and assistance systems. The MATRIX is suitable to seed beets, canola and root chicory.

The revised single row seeding unit

Modularity, weight optimization and precise spacing of the seed were at the forefront of the revision of the seeding unit. The parallelogram, which guides the single-row seeding unit in depth, is now made of hardened cast aluminum. The lower weight combined with increased rigidity ensures improved adaptation to the ground contour. In addition, acting forces can be better dissipated. Another new feature is that the parallelogram is equipped with maintenance-free plastic bearings. The increasing importance of mechanical weed control makes a precise, central placement of the seed in the row necessary. The newly revised parallelogram meets these requirements in a perfect way, thanks to its true-to-gauge seed-placement.

The new seed hopper has a lid that protects the seed against dust and water and can be closed tightly with a spring-loaded snapper.

The machine has a new optical sensor, which is now protected inside the seeding coulter. The sensor reliably detects and counts beet, canola and root chicory seed - even under difficult conditions. Furthermore, the new sensor reliably indicates possible blockages of the seeding coulter to the driver.

Thanks to the modular design of the single-row seeding unit, it can be converted from conventional seeding to mulch seeding. The row spacing can also be changed from 50 cm to 45 cm. The two setting options are particularly advantageous if the cultivation method changes over time due to new requirements.

Picture: The new MATRIX can be configured with equipment for mulch seeding (as shown) or for conventional seeding. (©GRIMME)

The new interchangeable seeding coulter system

The new, patent-pending coulter changing system has been developed for quick and easy changing. Only one screw needs to be loosened and one screw completely removed to replace the seeding coulters. Afterwards, the seeding coulter can be removed downwards. This reduces the workload enormously and makes the changeover much more pleasant.

Extended adjustment options for the cutting discs

The height of the entire cutting disk console can be adjusted by 1 cm to ensure that the cutting disks can be used for longer, even as wear progresses. The height can be adjusted in just a few simple steps.

Quick and tool-free adjustment

The new frame and single row concept allows the MATRIX to be adjusted without tools and without having to move between the rows.

To ensure that the seeding units of rows with a running wheel are also easily accessible, the running wheels can be folded up and locked into place without tools for maintenance and cleaning work.

Optional clod clearers can be set at 6 different heights using a hole grid with a cotter pin. The advantage is that the clod clearers are no longer mounted on the main frame, but in front of each individual seeding unit. This means that the height of the clod clearers can be set individually for each row.

The coulter pressure can be adjusted in five different stages (30 kg each) from 0 to 120 kg using an easily accessible handle. The seeding depth can be easily and precisely defined in 0.5 cm increments from 0 - 5 cm using a lever. In addition, the intensity of the rubberized intermediate press wheel as well as the discformed furrow closers and caster wheels can be adjusted using an easily accessible lever.

Picture: All adjustments can be made conveniently by hand without tools.. (©GRIMME)

Intelligent operating and assistance systems

For precise seed placement at different driving speeds, a radar sensor for slip-free speed detection was installed centrally under the main frame. Alternatively, the tractor's speed signal can be used. With the new intuitive GRIMME Digital Interface (GDI), operators can quickly find their way around and have all adjustable parameters at their fingertips. To maximize yield and save seed, Clever Planting is on board as standard and Section Control is available as an option.

This is new in connection with the so-called MATRIX seed: Within the machine width, each individual seed is placed in a triangular formation for an optimised crop distribution.

Another new feature is the creation of so-called turnpike-rows. This method increases the seeding rate in defined rows towards the edge of the field. This limits possible feeding damage to the outer rows, which at the same time promotes a homogeneous crop in the centre of the field until harvest.

With a view to the harvest, it is already possible to create so-called ‘harvest windows’ during seeding. This means that seeding is interrupted for a certain area. The resulting marking helps the harvester driver to find the right match of (6-12-18) rows in relation to the seeding process, increases harvesting efficiency and provides additional relief and driving comfort. The new generation of MATRIX will be in use for the 2024 canola seeding season and will be available in unlimited quantities for the 2025 season.

Picture: The so-called harvest-window is used by the harvester driver for improved orientation. (©GRIMME)

More from the GRIMME world

The VARITRON - Gentle on the crop. Strong results.

The VARITRON is more than just a self-propelled harvester: it is the gentle giant in the field, dedicated to powerful yet tender harvesting to attain the highest levels of quality!

GRIMME opens new branch in Fisantekraal, Durbanville, Cape Town

GRIMME opens new branch in Durbanville, Cape Town

Successful Agritechnica 2025

Good atmosphere at Agritechnica despite low producer prices.

Advanced digital developments at GRIMME

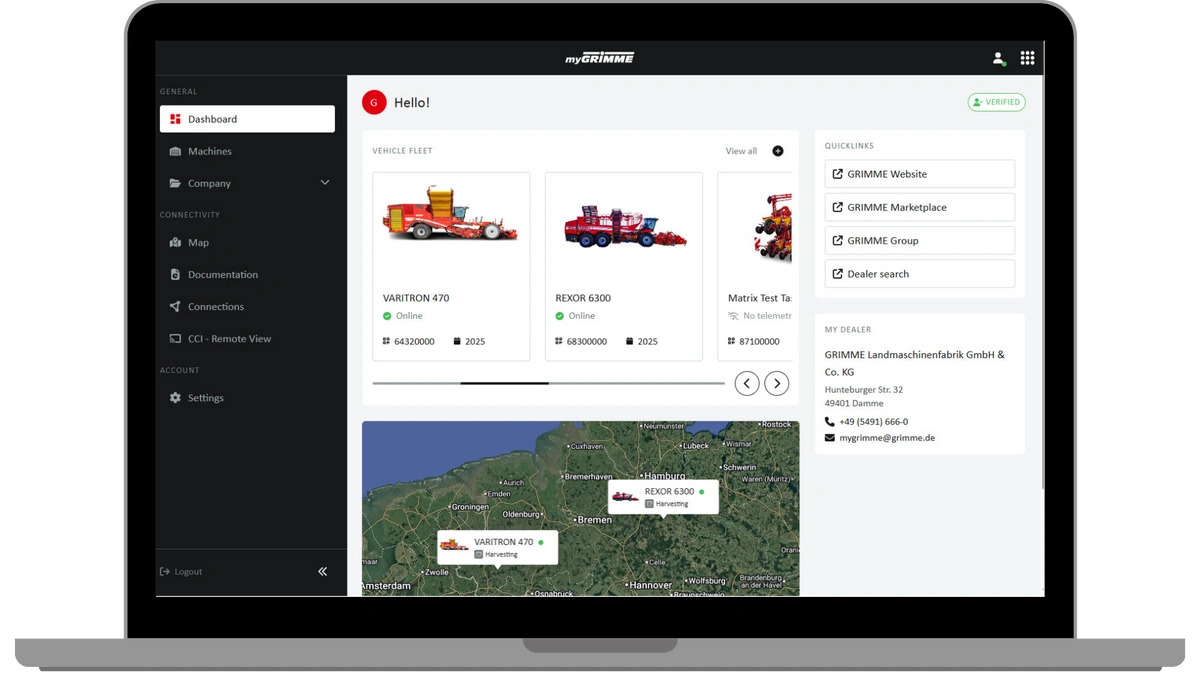

Revised myGRIMME User interface, new ISOBUS operator terminal and video system