CropAnalyser - site specific and variety-specific recording of tuber size and yield

Thanks to the CropAnalyser, it is possible to estimate the amount of impurities. The new system records tuber size and the resulting potato yield during the harvesting process for specific varieties and subplots.

Published on September 26, 2023 - from Kathrin Fühne

Thanks to the CropAnalyser, it is possible to estimate the amount of impurities. The new system records tuber size and the resulting potato yield during the harvesting process for specific varieties and subplots.

The system is based on the laser light-section method, in which the entire crop flow is captured by a laser camera setup, above the bunker filling elevator.

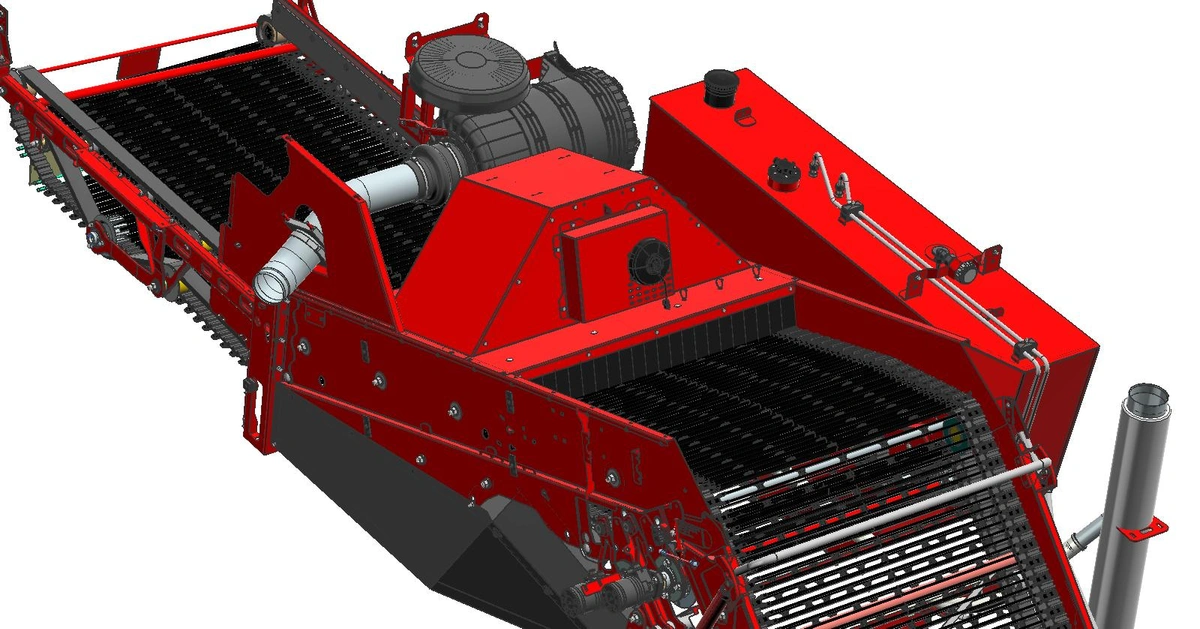

Picture: Concept of the sensor housing above the bunker filling elevator of a self-propelled potato harvester.

The collected data is automatically processed and visualized live for the operator of the machine and in the end customer portal "myGRIMME". With the application "Fields" in myGRIMME, the user has the possibility to display the variation of tuber sizes, the resulting estimated yield as well as the percentage of trash. The "Crops" application enables a variety-specific assessment of the parameters.

Picture: myGRIMME "Crops" application: Site-specific display of the variation of tuber sizes depending on the variety.

With the aid of "agrirouter" (an internationally acting agricultural data exchange platform), the data from the CropAnalyser can be transferred in a standardized manner to further systems, such as farm management information systems (FMIS).

In practice, this means that important information for the disposition, storage and marketing of potatoes is immediately available online. As a result, unnecessary transport-capacity can be avoided and the planning of downstream processes can be simplified. In addition, the grower can check the success of agronomic measures and varieties from planting to harvest on the basis of valid data. In the following years, potato cultivation can thus be further optimised. In addition, the workload for manual yield sampling can be reduced by automatically recording the yield and tuber size.

More from the GRIMME world

GRIMME MultiSep roller separator for receiving hoppers

For the 2026 season, GRIMME is offering the original MultiSep roller separator for the RH 24 series receiving hoppers.

The VARITRON - Gentle on the crop. Strong results.

The VARITRON is more than just a self-propelled harvester: it is the gentle giant in the field, dedicated to powerful yet tender harvesting to attain the highest levels of quality!

GRIMME opens new branch in Fisantekraal, Durbanville, Cape Town

GRIMME opens new branch in Durbanville, Cape Town

Successful Agritechnica 2025

Good atmosphere at Agritechnica despite low producer prices.