RICON develops innovative quick-change system for webs

RICON will be presenting the patented RICONDA main web with its unique, wear-resistant and maintenance-free connection system together with GRIMME at AGRITECHNICA 2025.

Published on September 22, 2025 - from Christina Klöcker

Main webs and other webs are exposed to very high loads and wear. In practice, it is often the connectors (web joiners) that wear out first. Replacement – especially in the field – is time-consuming, costly and involves a lot of assembly work. Replacing defective support and carrier rollers installed under the main web may also be very time-consuming, as previous connectors cannot be opened at every point.

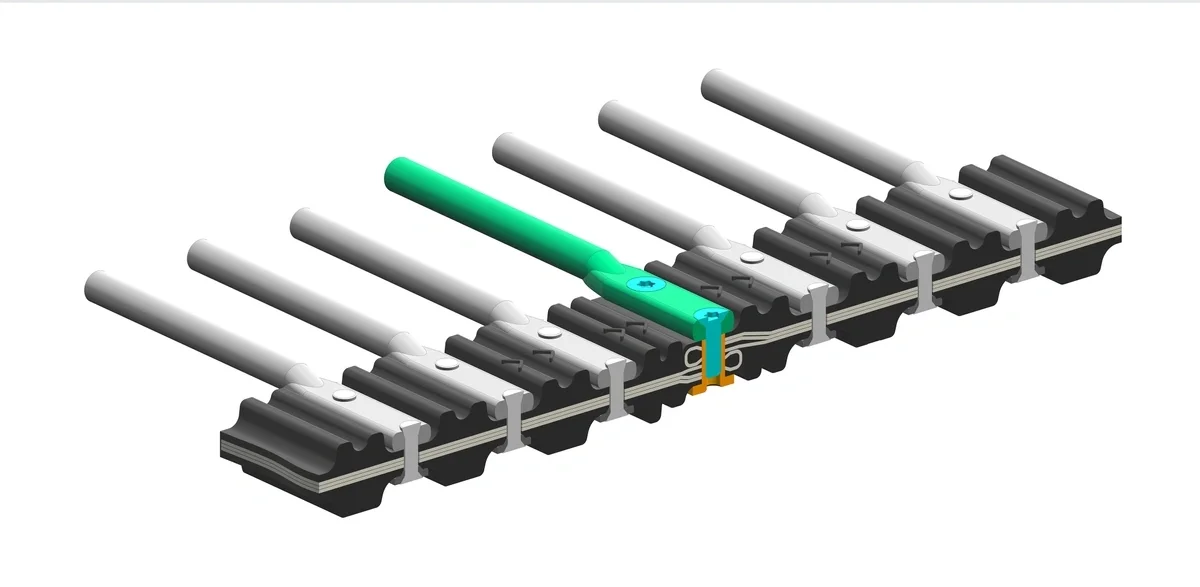

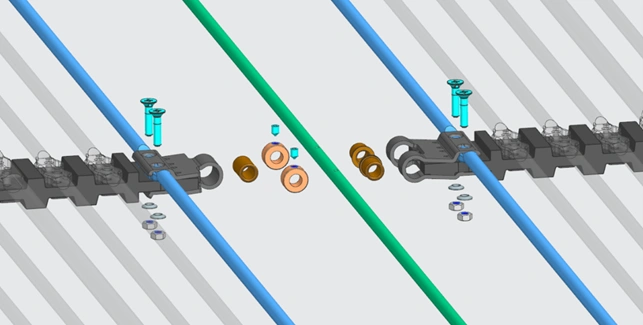

RICON will be presenting the patented RICONDA main web with its unique, wear-resistant and maintenance-free connection system together with GRIMME at AGRITECHNICA 2025. With this system, the web ends are vulcanised rather than clamped, resulting in significantly increased stability and a longer service life. The webs are connected via a very robust anchor plate, a web bar and two screws, thus requiring significantly fewer parts than standard systems. The webs can be opened at any point in the main web channel, e.g. to replace support rollers. This means that only one person is needed instead of two. The new, flexible connection also allows the use of smaller drive and deflection rollers to reduce drop heights. Another advantage is that different connectors are no longer required for each web pitch. One joiner for all pitches. Last but not least, the new connection area is largely maintenance-free.

‘With the RICONDA main web, our team has achieved a major innovation that eliminates the disadvantages of previous systems,’ explain RICON's two managing directors, Philipp Grimme and Felix Lingens.

INFO:

RICON GmbH & Co. KG develops and manufactures modern webs and conveying equipment with over 170 employees, primarily in the field of agricultural machinery and belt scrapers for the food industry. A total of over 8,000 different webs and conveyors are available. The company was founded in 1995 by Franz Grimme in Damme and has been based in the ‘Niedersachsenpark’ industrial estate in Rieste since 2011. RICON is managed by Philipp Grimme and Felix Lingens.

Webs are are essential components for separating soil, small stones and clods from the harvested crop.

The web-ends of the RICONDA web are vulcanised and not stapled. The anchor plate, the rod and two screws connect the web.

Conventional systems require significantly more parts and the web-ends are clamped instead of vulcanised.

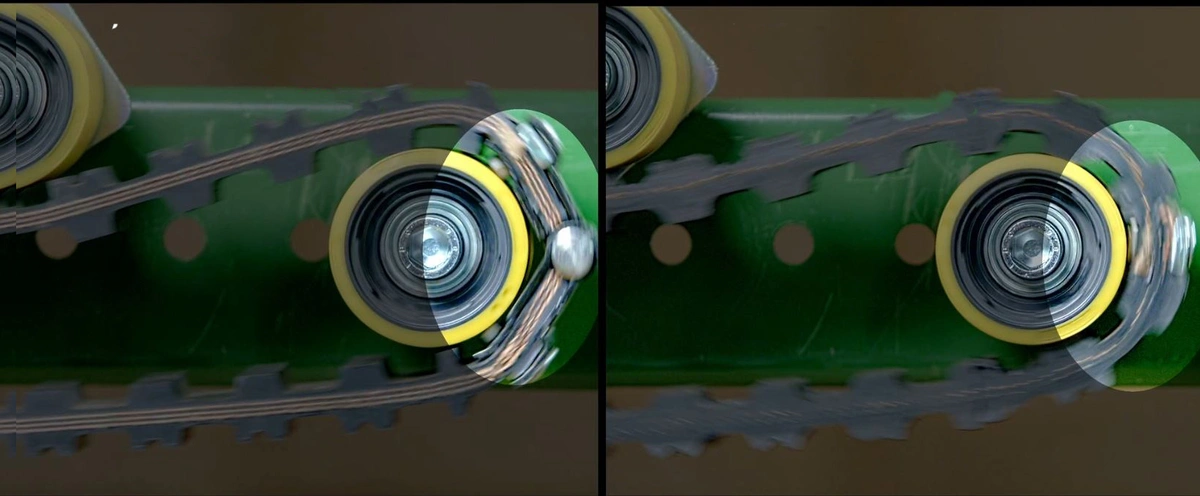

The RICONDA web (right) reduces the so-called ‘polygon effect’. The web runs much more smoothly around a deflection roller, allowing for smaller diameters that reduce drop steps.

RICON, Sieb- und Fördertechnik GmbH is based in the ‘Niedersachsenpark’ industrial estate in Rieste.

More from the GRIMME world

GRIMME MultiSep roller separator for receiving hoppers

For the 2026 season, GRIMME is offering the original MultiSep roller separator for the RH 24 series receiving hoppers.

The VARITRON - Gentle on the crop. Strong results.

The VARITRON is more than just a self-propelled harvester: it is the gentle giant in the field, dedicated to powerful yet tender harvesting to attain the highest levels of quality!

GRIMME opens new branch in Fisantekraal, Durbanville, Cape Town

GRIMME opens new branch in Durbanville, Cape Town

Successful Agritechnica 2025

Good atmosphere at Agritechnica despite low producer prices.