The update for the two-row VARITRON harvesters from GRIMME

GRIMME introduces the new generation of the two-row, self-propelled VARITRON series.

Published on April 10, 2025 - from Kathrin Fühne

GRIMME introduces the new generation of the two-row, self-propelled VARITRON series. The optimisation of the series focused on the new cab with a revised operating concept and various improvements along the crop flow for harvesting vegetables and potatoes.

Picture: The new design is available for the VARITRON 220, VARITRON 270 and VARITRON 270 TERRA TRAC.

The new cab with integrated operator terminal CCI 1200 and SmartView video system

The new, very clearly laid out cab impresses with generous legroom, narrow pillars and a 2-zone automatic climate control system. The large windscreen provides an unobstructed view of the intake. A swivelling leather seat rounds off the convenient and intuitive operation via the large CCI 1200 operator terminal with the GRIMME Digital Interface (GDI), in addition to many other detailed improvements. All functions can be monitored with up to 13 cameras on a 12 inch display of the SmartView video system. In addition to the flexible operation layout, the features of zooming and live slow motion are included as standard. All-round visibility at night and in poor weather conditions is favoured by the new LED lighting. For the documentation of harvest masses, the VARITRON can be equipped with an integrated system for mass mapping.

Picture: The additional two SideView cameras eliminate blind spots at the rear of the machine.

An intake with various possibilities

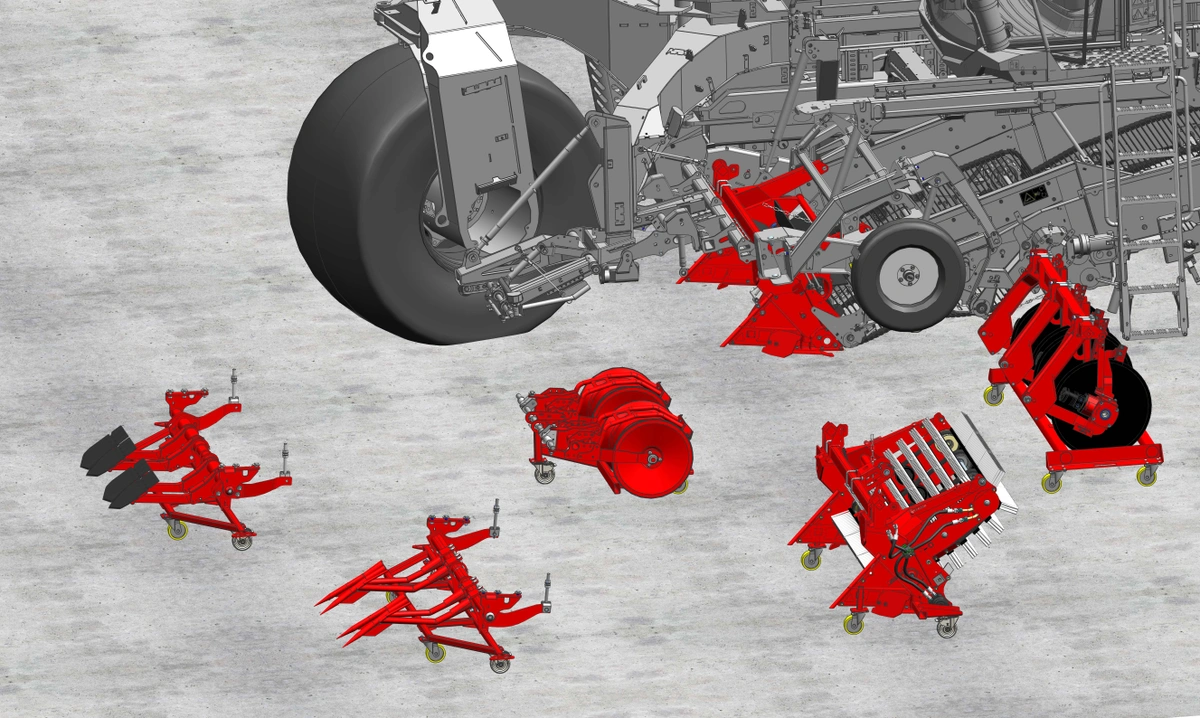

In order to be able to use the new two-row VARITRON models flexibly in a wide range of conditions and crops, an interchangeable device is available for exchanging the intake components. This facilitates variable use in various crops enormously and can be realised in a time-efficient manner. The proven concept of depth control remains in place with ‘TerraDisc’ and ‘TerraControl’. Uniform mechanical coupling points enable quick changeover, similar to what is already known from the GRIMME four-row harvesters.

Picture: Thanks to the harmonised mechanical coupling points, it is possible to quickly switch between different components, for example for the intake of windrowed crops or for harvesting carrots.

Improvements along the crop flow when passing the separators

A new spiral roller is available for the roller separator, in which the material composition has been changed and the height of the spiral almost doubled. This increases the passage for impurities, boosts the separation performance and reduces wear on the rollers.

The combination of a double-separator with a downstream fitted fine haulm elevator is unique in this machine class. The double-separator can be configured as a Double-MultiSep or as a roller separator in combination with MultiSep. The GRIMME specific TwinSep can be used as a crop-friendly bypass to the roller separator.

To remove and to prevent any blockage, all main webs, the fine haulm elevator and the ring elevator can be individually and conveniently reversed from the operator cab.

Comfortable workplace at the picking table

The optional weather roof, available with or without side panels, protects the picking crew in all weathers. The white roof tarp is colour-neutral and supports the reliable recognition of green tubers.

More from the GRIMME world

GRIMME MultiSep roller separator for receiving hoppers

For the 2026 season, GRIMME is offering the original MultiSep roller separator for the RH 24 series receiving hoppers.

The VARITRON - Gentle on the crop. Strong results.

The VARITRON is more than just a self-propelled harvester: it is the gentle giant in the field, dedicated to powerful yet tender harvesting to attain the highest levels of quality!

GRIMME opens new branch in Fisantekraal, Durbanville, Cape Town

GRIMME opens new branch in Durbanville, Cape Town

Successful Agritechnica 2025

Good atmosphere at Agritechnica despite low producer prices.