undefined undefined

Vertrieb

CropAnalyser - site specific and variety-specific recording of tuber size and yield during potato harvesting process

Thanks to the CropAnalyser, it is possible to estimate the amount of impurities.

Veröffentlicht am 28. September 2023 - von Kathrin Fühne

The new system records tuber size and the resulting potato yield during the harvesting process for specific varieties and subplots.

The system is based on the laser light-section method, in which the entire crop flow is captured by a laser camera setup, above the bunker filling elevator.

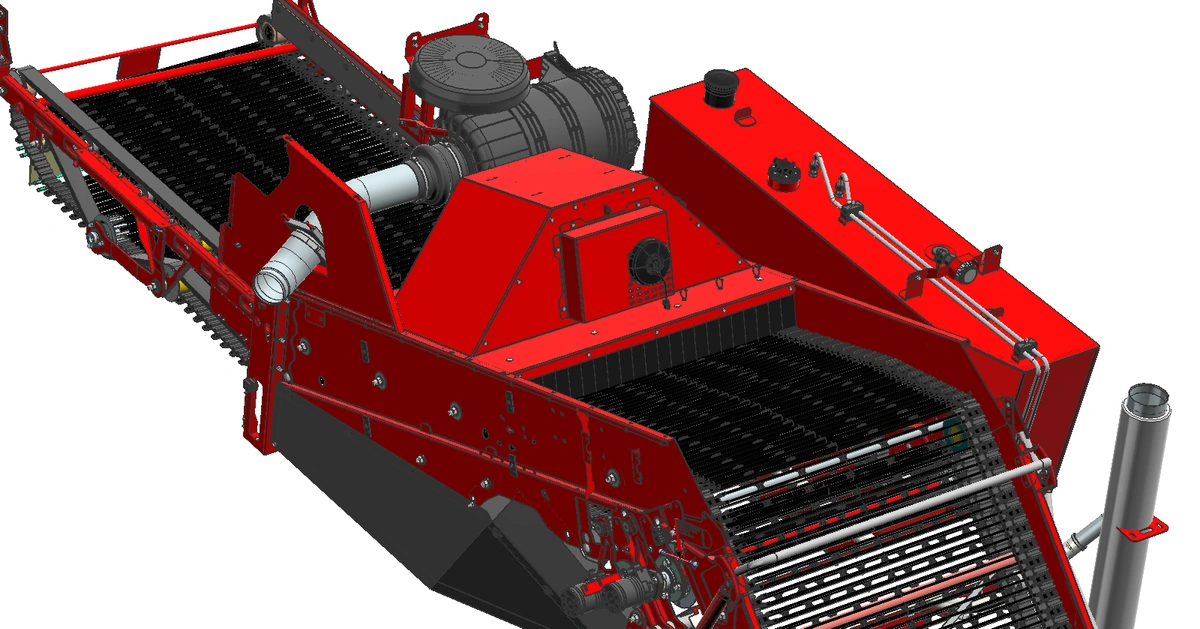

Picture: Concept of the sensor housing above the bunker filling elevator of a self-propelled potato harvester.

The collected data is automatically processed and visualized live for the operator of the machine and in the end customer portal "myGRIMME". With the application "Fields" in myGRIMME, the user has the possibility to display the variation of tuber sizes, the resulting estimated yield as well as the percentage of trash. The "Crops" application enables a variety-specific assessment of the parameters.

Picture: myGRIMME "Crops" application: Site-specific display of the variation of tuber sizes depending on the variety.

With the aid of "agrirouter" (an internationally acting agricultural data exchange platform), the data from the CropAnalyser can be transferred in a standardized manner to further systems, such as farm management information systems (FMIS).

In practice, this means that important information for the disposition, storage and marketing of potatoes is immediately available online. As a result, unnecessary transport-capacity can be avoided and the planning of downstream processes can be simplified. In addition, the grower can check the success of agronomic measures and varieties from planting to harvest on the basis of valid data. In the following years, potato cultivation can thus be further optimised. In addition, the workload for manual yield sampling can be reduced by automatically recording the yield and tuber size.

Weiteres aus der GRIMME Welt

Historischer GRIMME Roder für das KRONE Museum

Am 22. Juli 2024 überreichten Gebhard Gerken, Dr. Michael Tönnies und Jürgen Feld einen Schleuderradroder (Kombi) mit Auffangkorb (Unerreicht) an das KRONE Museum des gleichnamigen Landmaschinenherstellers aus dem emsländischen Spelle.

Ferienbetreuung bei GRIMME!

Vom 01. bis 12. Juli 2024 konnten die Kinder (Alter 10 - 14 Jahre) der GRIMME Mitarbeiter eine Ferienbetreuung der neuen Art erleben. 26 Kinder haben in der GRIMME Wissenswerkstatt ihre handwerklichen Fähigkeiten unter Beweis gestellt und beim Sport in Kooperation mit Rot Weiß Damme ihre sportlichen Talente gezeigt. Ein ...

Zuckerrübenausschuss zu Gast bei GRIMME

Die Familie Grimme und die Geschäftsleitung tauschten sich an zwei Tagen intensiv über die Herausforderungen in der Zuckerbranche mit den Mitgliedern des Redaktionsausschusses der Deutschen Zuckerwirtschaft aus.

15. Krönung der Deutschen Zuckerrübenkönigin

Am 29. Juni 2024 wurde Ingrid Stigler aus Oberaichgarten zur 15. Deutschen Zuckerrübenkönigin gekrönt.

Du möchtest keine Neuigkeiten mehr verpassen? Bleibe immer mit uns in Verbindung.

Melde Dich für unseren Newsletter an und bekomme die Neuigkeiten von GRIMME aus erster Hand.