AIRSEP 290 - The harvesting specialist for stony soils

At the Agritechnica 2013, GRIMME and SPUDNIK, which is also part of the GRIMME Group, presented the AirSep separator, which was awarded the highest award of the German Agricultural Society (DLG) - a DLG Gold medal.

Published on August 16, 2024 - from Christina Klöcker

At the Agritechnica 2013, GRIMME and SPUDNIK, which is also part of the GRIMME Group, presented the AirSep separator, which was awarded the highest award of the German Agricultural Society (DLG) - a DLG Gold medal. This separator, which is particularly suitable for stony soils, has undergone extensive further development in recent years and has been integrated into an independent new machine series - called AIRSEP 290. Numerous changes, such as the modified crop flow and the optimised installation position of the AirSep blower, significantly increase reliability and stability.

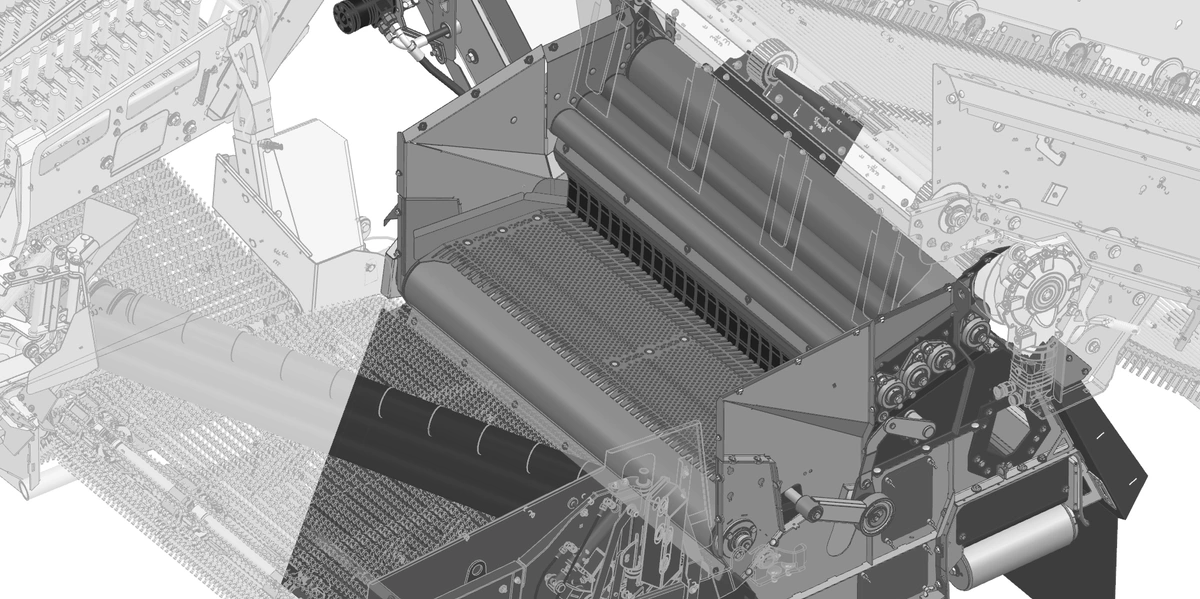

Picture: The modified air guidance in the pressure duct made it possible to reduce the speed of the AirSep blower and thus the load on the drive train, which increases efficiency and enables higher throughput rates. (©GRIMME)

Stepless adjustment of the main web speed

The AIRSEP 290 is equipped with a fully hydraulic drive. This means that all main webs, including the optionally available intake web and the separators, can be adjusted independently of the engine speed (PTO speed) of the tractor.

The avoidance of mechanical drive components also improves accessibility for cleaning and maintenance work. The speeds of all main webs, including the deviner web, are now displayed in km/h, making it easier for the driver to adjust the web speeds in relation to the forward speed of the tractor. The speeds of the second main web and deviner web can be set independently of each other. If desired, electronic assistance systems like Speedtronic-Web and Speedtronic-Sep relieve the operator by automatically regulating all web speeds.

Optimisations along the crop flow

The optimisation of the intake design ensures reduced weight as well as improved adaptation to the ground contour, which prevents build-up and blockage by haulm. For improved crop protection and reduction of possible losses, the overlap between the first and second main web has been increased. The optimised placement of the drive for the deviner web has increased both pulling power and durability. The centrally installed lubrication rails for the bunker and axle make it much easier and faster to maintain the machine. An automatic lubrication system is also available as an option. The boulder box was also enlarged to a capacity of around 1 m³.

Picture: At the transfer from the 2nd main web to the AirSep-separator, the feed belt has been replaced by hydraulically driven plain rollers, which improves the crop feed. (©GRIMME)

More space and comfort for picking staff

Further improvements have been made to increase convenience for the picking staff . The platform on the left-hand side of the machine can be extended so that up to 5 people can work comfortably at the picking table. Height-adjustable steps are also available, which allow the picking staff to work at a comfortable height. Also available are a waterproof storage box, stuffing on the picking table, drink holders and a 15-litre hand wash tank.

Overall, the above-mentioned upgrades have significantly improved the reliability and stability of the machine, meaning that series production of the AIRSEP 290 will begin in 2024 with its new, functional design.

Picture: The AIRSEP 290 is available as standard with a conventional 9 t bunker and optionally with the patented 7.5 t NonstopBunker with a large overloading width. (©GRIMME)

More from the GRIMME world

The VARITRON - Gentle on the crop. Strong results.

The VARITRON is more than just a self-propelled harvester: it is the gentle giant in the field, dedicated to powerful yet tender harvesting to attain the highest levels of quality!

GRIMME opens new branch in Fisantekraal, Durbanville, Cape Town

GRIMME opens new branch in Durbanville, Cape Town

Successful Agritechnica 2025

Good atmosphere at Agritechnica despite low producer prices.

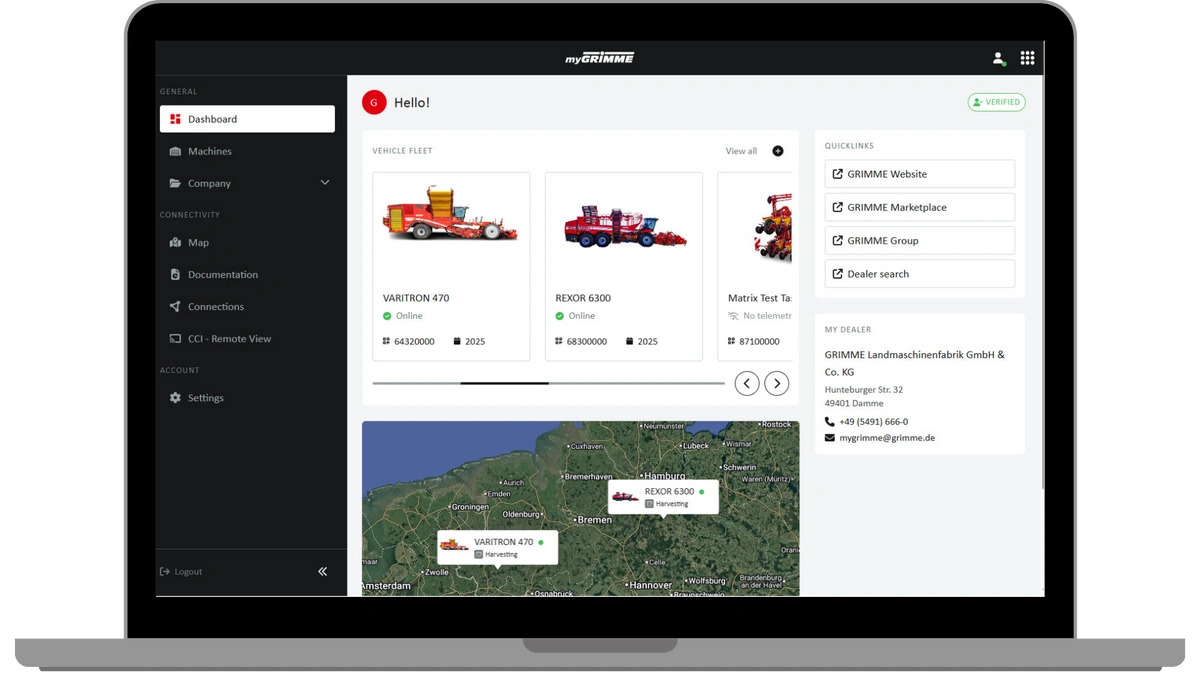

Advanced digital developments at GRIMME

Revised myGRIMME User interface, new ISOBUS operator terminal and video system